- Whether engineers are working in a product development laboratory or performing field tests, they must have the necessary instruments to respond quickly to new test requirements.

- As a result, procurement departments are often forced to place rush orders to meet their needs when the necessary instruments may already be part of the company’s test and measurement equipment pool.

- The implementation of an instrument fleet management system based on an asset management software platform such as the one offered by Electro Rent, for example, makes it possible to locate the available test equipment, thus avoiding the need to purchase additional equipment.

Author Dirk de Waart, Managing Director of Electro Rent

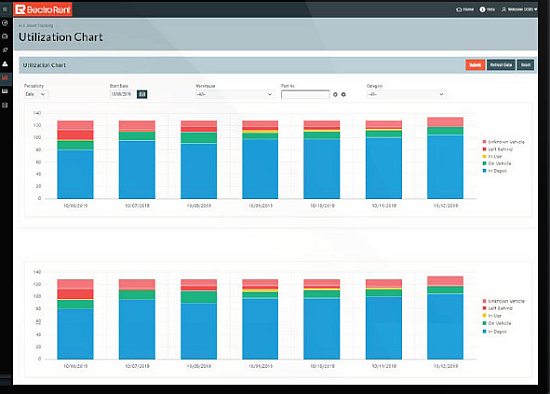

Research has shown that, in the majority of cases, a company’s use of test equipment will be in the range of 20% to 30%. The reason for this under-utilization is usually due to a lack of information about the equipment – its location, actual use, current condition, last maintenance, calibration, etc. – and the lack of information about the equipment itself.

By relying on data to enable a complete resource assessment, even the most extensive business operations are better able to know the availability of test resources to meet peaks and troughs in demand. As a result, equipment utilization is optimized and test activities are completed more quickly and efficiently. In addition, by identifying and then eliminating unused test equipment, you can free up space for other purposes. You no longer need to consider the additional costs associated with owning such equipment (such as insurance, maintenance, and financial facility deadlines). In addition, such equipment will often have a reasonable resale value, which may strengthen cash reserves.

All of these issues are addressed by having a well-orchestrated asset management system in place. This means that accurate data on the test equipment present within the company, covering many sites, can be made available to staff. The details that can be reviewed will include the technical specifications of a particular piece of equipment, its availability (whether it is currently assigned to a project, and for how long), whether it requires maintenance, where it is located, etc. From there, staff members will be able to make more informed decisions on how to allocate resources in the most efficient manner, and to judge whether more assets need to be acquired to meet the workload.

Based on many years of experience in this area, Electro Rent’s highly advanced Asset Optimization (AO) platform provides test technicians, as well as the logistics and procurement personnel supporting them, with complete visibility into the entire test equipment inventory. This can be referenced from the administrative departments, via a desktop computer, or via the warehouse and field test personnel using an intuitive mobile application.

With the parameter search function, asset requirements can be better linked to asset availability. This is a much more efficient approach than searching a database using just a part number or basic description. By analyzing asset usage figures, surplus equipment can be identified and steps can be taken to find a suitable buyer for it.

Let’s illustrate some of the points raised here with a few examples. A leading satellite manufacturer approached Electro Rent for assistance with its asset management challenges. The company was struggling to track and manage the extensive inventory of test equipment it had accumulated. This inventory included more than 10,000 different units, spread across several locations. Although utilization levels were very low, additional equipment still had to be purchased on a regular basis because the instruments in stock were difficult to find (or were not ready for immediate use). By applying Electro Rent’s AO solution to the situation, the customer was able to make dramatic changes. A complete audit of the stored assets was undertaken. In addition, some major bottlenecks were discovered in the calibration and repair processes. After resolving these issues, the company was able to reduce its downtime by 55%. And unplanned purchases were reduced by 70%.

In another case, after three months of using Electro Rent’s AO solution, the R&D division of a major semiconductor manufacturing company was able to significantly streamline its testing operations. It determined that 12% of the test assets in inventory were no longer in use and could be sold. This generated additional cash to allow for the purchase of new equipment needed for other tasks.