- The use of electric vehicles will only become widespread with the development of a dense and extensive network of battery charging stations.

- The charging stations must quickly recharge the batteries of electric vehicles and measure the electrical consumption with the reliability and accuracy necessary to bill the charging operation.

- In this article, Lem presents the main differences between AC and DC chargers and the advantages of its DCBM 400/600 meter.

By Mathieu Beguin, Global Product Manager at Lem

With transportation accounting for over 20% of global CO2 emissions in 2020 and 17% of all greenhouse gas emissions (according to Statista), decarbonization is essential in this sector. However, the massive challenge facing those who work within the transportation market, particularly suppliers, is to facilitate growth in the use of electric vehicles (EVs) while still giving end users a ‘gas station’ like experience. Take-up will only increase in line with global plans if the shift to EVs is made as smooth and painless as possible.

By 2030, Deloitte has predicted that there will be over 30 million EV sales around the world, with the US representing 14% of the global EV market (Europe 27% and China 49%). However, while advances in battery technology forge ahead in this sector, there is a major factor that could put the brakes on this brave new dawn – the availability of a sound charging infrastructure. Charging stations not only need to be readily accessible but they also need to be capable of charging vehicles in the shortest time possible and enabling EVs to travel maximum distances between ‘refuelling’.

Another issue is how those who develop a charging infrastructure are able to ensure they can bill users fairly and accurately. In short, charging stations need to be plentiful, rapid, reliable, safe, affordable and smart.

Adapted energy meters

Working to make all of this possible is LEM who has been providing components for electric vehicle charging stations (EVCSs) across Europe since 2020. The company is now actively supporting key players in the US’s electric transportation industry by supplying very high technology energy meters that will enable the North American EV charging infrastructure to expand and meet demand.

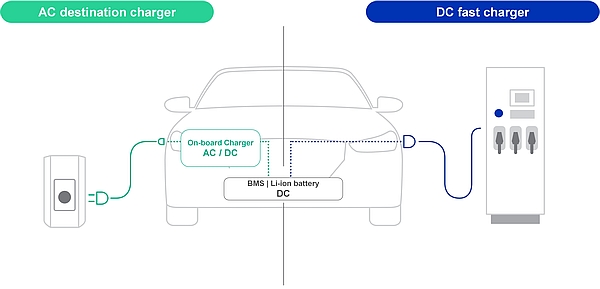

Two main methods of powering an EV are available – alternate current (AC) chargers and direct current (DC) chargers. Known as Mode 3 (level 2) for EVs, AC chargers are the most common charging solution on the market, enabling a vehicle to be charged directly via a standard home socket or community-based charging unit. Among the benefits of AC charging technology are affordability (due to a less complex electrical architecture), small footprint and transportability. However, downsides include limitations in terms of power delivered, with AC chargers only capable of providing between 3.7kW and 44kW, and charging power limited by the power of the conversion that takes place in the EV’s on-board charger (OBC). Because EV batteries have to be charged with a DC current, an AC/DC inverter must be fitted to every vehicle to carry out the required conversion and this can mean EV charging times of between two and 12 hours.

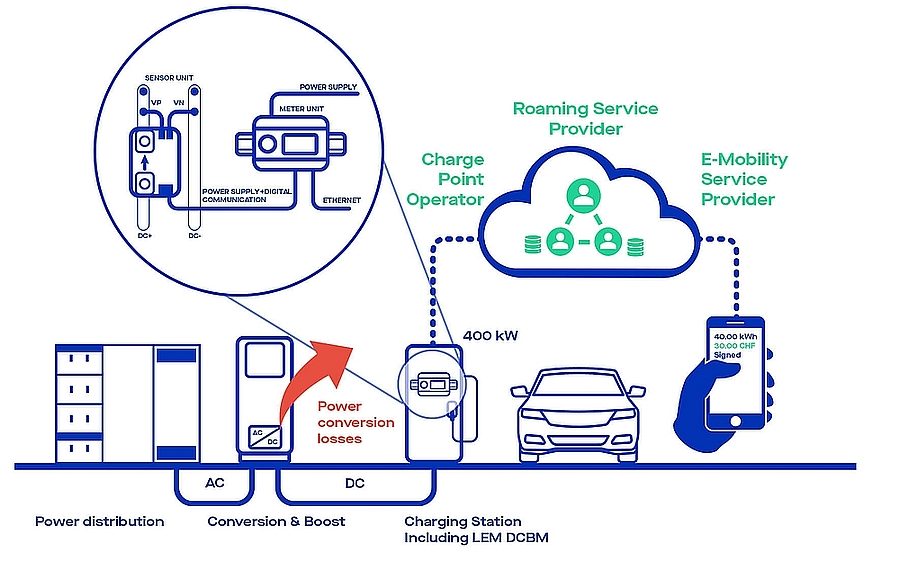

This isn’t the case when using DC chargers, also known as Mode 4 (level 3) or direct current fast charging (DCFC) devices. Providing 600V with a maximum current of 400A, DC chargers offer the benefit of converting AC from the grid into DC before it is delivered to the EV, which means the battery can be charged directly, bypassing the OBC and removing the need for an inverter. DCFC operates at powers from 25kW to over 350kW, which means a charging session for an EV has the potential to be reduced to as little as 15 minutes. However, although this method can boost charging power up to 400kW, the conversion stage generates power losses which are not paid for by the end user.

Precise and fair energy billing

How then can EVCS providers ensure billing of DC chargers has been carried out with precise accuracy? The answer is to use an electric meter after the conversion stage which will monitor the exact amount of energy that is transferred to the electric vehicle and allow for legal DC billing.

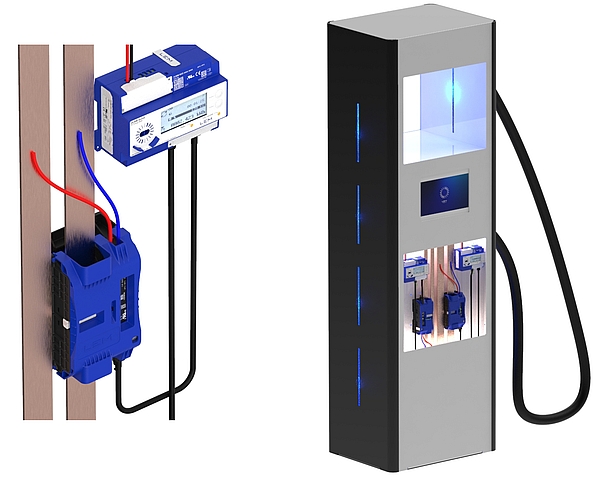

The solution developed by LEM, a specialist in energy measurement and metering for charging infrastructures, is the smart and compact Direct Current Billing Meter (DCBM), a plug-and-play solution designed with data security, e-mobility, digitization and flexibility in mind.

Created to help those responsible for operating and retrofitting electric vehicle charging stations take advantage of the benefits of rapid DC charging, the latest DCBM 400/600 model offers a power measurement range from 25kW to 600kW and an LCD display that shows real-time measurements, energy, alarms and legal data. Because it complies with all metering standards and uses industry standard data protocols, the meter ensures secure communications, authentic billing, easy connectivity to Cloud services and a faster certification process in compliance with metrology regulations.

The UL certification for the new DCBM means it is a UL recognized component for Canada and the United States (the certification is in the FTRZ category for EV applications). As with all the sensors LEM sells on the US market, to achieve this certification the DCBM had to go through a rigorous audit focusing on electrical safety and needed to be compliant with ambient operating temperatures up to 158°F. The DCBM is accurate and correct over a temperature range of -40°F to +185°F.

UL certification

More specifically, the meter underwent a series of gate reviews and tests related to the well-known UL 61010 and UL 810 standards, including reinforced insulation tests, temperature testing of all its components and sub-assemblies, testing for protection against electric chock, durability of markings tests, equipment temperature limit tests and resistance to heat/fire risk tests.

For manufacturers of EVCSs in the North American market, this UL recognized certification reassures them of the viability of the DCBM and simplifies the process of them having to qualify their own charging station for UL listed certification, accelerating time to market for their equipment. For added peace of mind, the meter is required to undergo a new audit every quarter.

A major feature of the DCBM is its build of exemplary quality. Even though thousands of the meters have been installed already in the European EVCS market over recent years – where the product has Module B and D certification – no issues have been reported. Indeed, customers have reported how the device’s two-piece architecture makes rapid installation straightforward, even when retrofitting on to existing electric vehicle charging stations. Integration is made easy, they say, by the meter’s genuine plug-and-play design.

Deployment and integration of the meter

The DCBM 400/600 is certainly a product for the 21st century, with future connectivity built in thanks to its Ethernet communication capability. Supporting the HTTP/REST protocol and Network Time Protocol (NTP) time synchronization makes it easy to deploy and integrate the meter into a wide range of charging stations. Long-term application is also enabled through the DCBM 400/600 being bi-directional, which ensures compatibility to V2G (vehicle-to-grid) and V2X (vehicle-to-everything) under the ISO 15118 standard.

As well as delivering total transparency of billing data for users, LEM’s EVCS meter integrates the signed billing data sets according to the Open Charge Metering Format (OCMF) protocol. OCMF enables billing data to be handled with an extremely high level of security and total interoperability for Cloud service operators using the Open Charge Point Protocol (OCPP) format. Although not yet widely adopted in the US, OCPP is an important application protocol for communications between an EVCS and a central management system.

Other features of the DCBM 400/600 include a datalink cable available in sizes of 30cm to 3.5m, a range of operation of 150V DC to 1000V DC, robust wide current terminals compliant with busbars, auxiliary power supply range of +12V DC to +48V DC, DIN rail 35mm and screw mounting, and an IP20-rated casing.