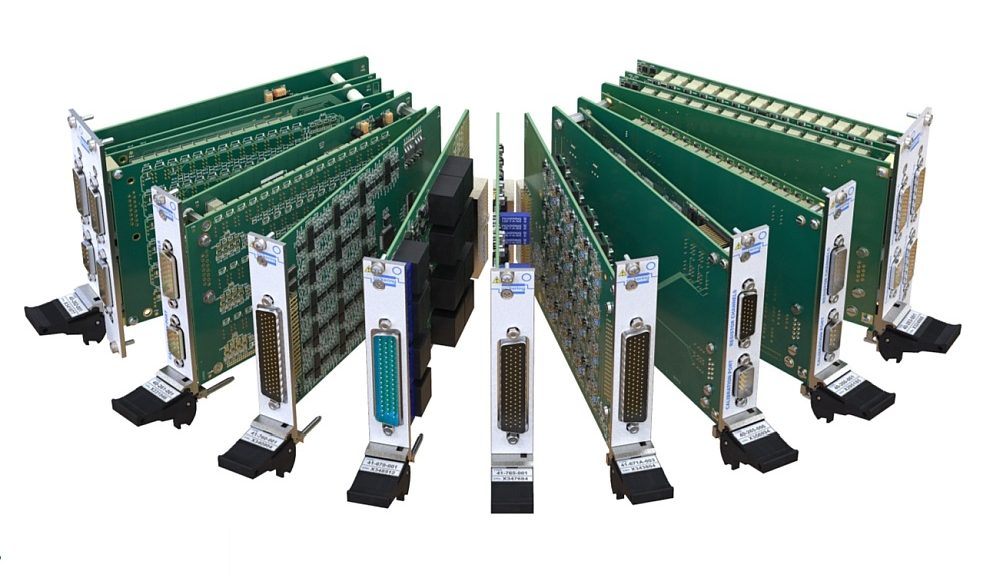

- Pickering Interfaces is one of the leading specialists for modular switching solutions. However, its offering is not limited to multiplexers and other switching matrices.

- Over the years, the company has built up an extensive range of PXI sensor simulation boards, which now accounts for almost a third of its sales.

- The UK company, which offers no less than 300 references of boards simulating a wide variety of sensors, has just extended this range with the launch of the PXI 41-670 board for the simulation of LVDT, RVDT sensors and resolvers, and the PXI 41-765 module for the simulation of 4-20 mA current loops.

Airplanes, UAVs, spacecraft, automobiles, trains and ships, like most automated industrial equipment, cannot do without the sensors they carry on board in large numbers in order to operate. A wide variety of sensors are available on the market to measure temperature, pressure, stress, position, displacement, vibration, etc. Each type of sensor exists in hundreds of variants to meet very specific measurement requirements and environments.

The PXI simulation boards offered by Pickering Interfaces are designed to replace a large number of these sensors in a Hardware-In-The-Loop (HIL) simulation system. HIL test applications are complex to implement. They aim to validate the operation and safety of the software that drives the on-board electronic processing units. They are generally very safety-critical applications in sectors such as aeronautics, automotive or railways. Each time new software is used or updated, it must be revalidated, fully simulating its end-use environment, including the sensors. In aeronautics, for example, a FADEC jet engine controller uses data from hundreds of temperature, pressure, rotation, etc. sensors. All these elements must be simulated within a HIL system.

Pickering has developed a wide range of solutions for simulating the operation of sensors commonly used in the aerospace, automotive and industrial sectors. Its offer includes a variety of boards for the simulation of resistors, RDT (Resistance Temperature Detector), strain gauges, thermocouples, LVDT/RVDT/Resolver sensors, current loop, analog signals, etc.

“We offer more than 300 simulation boards for sensors and other analog signals. Each family is available in several models depending on the measurement range, accuracy or number of channels required for the application. If none of our references are suitable for a customer’s application, we can develop a solution that will meet the customer’s exact requirements. We are a highly integrated company. We have in-house control of the entire manufacturing chain, from design to production of the electronic boards and their wiring. As a result, we can support our products for up to 15 to 20 years,” explains Keith Moore, Pickering’s CEO.

Simulating sensors instead of using real sensors reduces both cost and time since there is no need to acquire the sensors or install and wire them on a test bench. In addition, the configurable simulation boards can be reused for other applications. “By using sensor simulation, software test systems become more accurate, faster and more repeatable. They are less complex in terms of wiring and the use of discrete components. And it’s all contained in a single test rack,” says Keith Moore.

In addition to its range of PXI switch modules, Pickering also has fault insertion cards (open or short circuit) to extend the simulation capabilities of an automated test system.