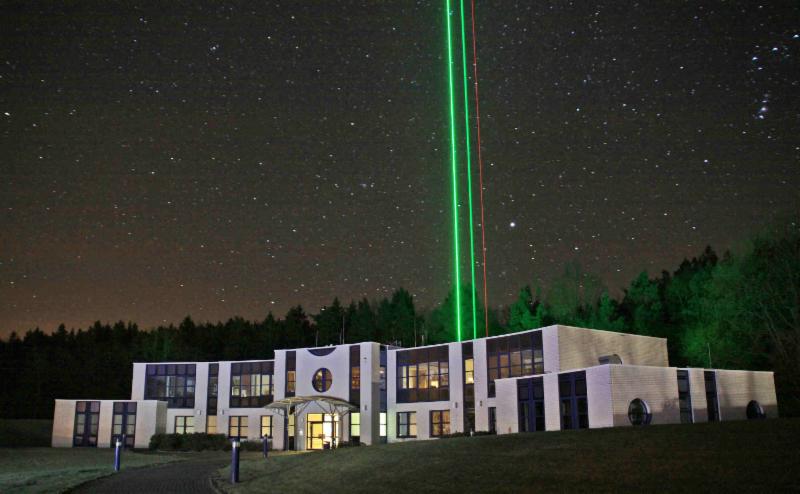

- Atmospheric research uses pulsed laser beams to measure temperature and wind speed along the beams by measuring the Doppler shifted and backscattered light at 100 km height in the atmosphere.

- The returning light signals are very weak and can be blocked by sunlight, but The Leibniz Institute for Atmospheric Physics (IAP) has solved this problem: they developed an portable instrument that can be used during the daytime.

- This new generation of systems uses a novel, diode-pumped laser and, at its heart, are a Spectrum Instrumentation Arbitrary Waveform Generator (AWG) and two Digitizers that provide the speed, sensitivity and real-time capability required.

- It has already provided new insights into Antarctic atmospheric conditions.

The measuring technique is called Doppler resonance LIDAR as the light is backscattered by tuning the laser precisely to a resonance transition of a metal atom. The backscattered signals are extremely weak (single photons per laser pulse) and are almost completely drowned out by solar radiation during the day. The difference between night and day measurements is that there is 100,000,000 times more background noise during the day from the sun.

Understanding temperature distributions in the atmosphere at altitudes between 80 and 110 km, called the MLT (Mesosphere and lower Thermosphere), is crucial for performing numerical simulations of the Earth’s climate. One well-established approach to provide such data is to measure the Doppler broadened line width of metal atoms, e.g. of the potassium resonance line at 770 nm and of the iron resonance line at 372 nm or 386 nm, by means of resonance LIDAR systems using pulsed lasers. Until now, these lasers have used flashlamp-pumps, but this project is the first to develop a novel laser system using a highly efficient, tunable, diode-pumped, alexandrite laser that is better able to cope with rough environmental conditions such as on research ships or in polar regions. With this technology, a concentration of about 1 atom per cubic centimeter is sufficient for temperature and wind measurements at 100 km distance, which is an altitude where the atmospheric pressure is so low than only rockets can access this altitude.

Dr. Josef Höffner, who is leading the project, explained, “The aim of the project is to create compact mobile measurement systems that we can take around the world. Such systems require automatic operation under extreme environment conditions like Antarctica without access to them for long periods of times. We therefore need components that are very robust and reliable as well being able to provide the levels of sensitivity, speed and flexibility required under these challenging conditions. Spectrum’s five-year warranty gives us peace of mind that these critical items can be relied on.”

There are several aspects to improving the measurements in this project. The first is suppressing the background noise by having an extremely small field of view for high resolution, optical filtering and small field of views. This means that the laser has to be stabilized in the field of view as well as all filters. The laser itself requires a complex and fast real-time stabilization system with nanosecond timing. This is controlled by the Spectrum M2i.6012 20 MS/s AWG and fires at 500 pulses a second for 24 hours a day. The signals from the backscattered light are processed by the Spectrum M4i.4421 250 MS/s 16-bit digitizer. The conditions within the laser are measured with a M4i.2221 2.5 GS/s 8-bit digitizer card. The system handles more than 1 GByte/sec for 24 hours a day with a response time of about 1 ms after processing the measured data in real-time. In total, 21 signals are managed by a software package developed at the IAP.

“We have achieved a compact, highly integrated solution by combining fast, flexible electronics with real-time capability, which is an impressive improvement compared to the previous, large and difficult-to-handle solutions that were many times bigger,” said Dr. Höffner. “Our old system needed a 10 ton, 6 m container and this has been shrunk to a 1500 kg system using the Spectrum cards and a novel laser. We have nearly finished shrinking this even further to fit into a one-meter cubed box of only 250 kg, which will use the same electronics and a more compact and advanced laser.”